As each race goes by, teams are accruing more data and have a better understanding of how to maximise performance, while combating the ill effects posed by porpoising.

The phenomenon, which caught the majority of the grid by surprise when their cars first hit the track, has been the main focus for teams as reducing its amplitude will unlock more performance. All of the teams suffered from porpoising to one degree or another, owing to a number of factors which result in its appearance.

A simplistic approach to quieting down the issue is to raise the car’s ride height but this would not only compromise the aerodynamic performance but also dramatically narrow the set-up options available too. For many, this means a more root and branch approach has to be sought, with some teams having to be more pragmatic about how long it will take to find an appropriate fix.

In the meantime, the development battle rages on and teams have been busy using new floor designs – not only as a means of improving aerodynamic output but also in order to save weight. The latter is exceptionally important when we consider that a large proportion of the grid hasn’t been able to make the minimum weight, even with it raised just ahead of the season to an eye-watering 698kg.

Given the increased loads that the floor now sustains, teams had to build in some additional margin. While some of that will have been removed by having a better understanding of the real world loads that are imparted upon different areas of the floor, the late change in the regulations to include a metal support stay ahead of the rear tyre has also been significant. This not only reduces porpoising but also offsets the rigidity it affords against any weight reduction plans.

Taking into consideration the lead time to manufacture the floor, which is by far the largest component installed on the car, the teams have opted for a patchwork-quilt style approach, allowing them to swap out sections of the floor, rather than having to manufacture an entirely new floor each time.

While this does add some weight, it makes them extremely agile when it comes to development and reduces costs, which is an extremely important factor when we consider the ramifications of the cost cap on teams this season.

Ferrari F1-75 and McLaren MCL36 floor comparison

Photo by: Giorgio Piola

Mercedes W13 new floor comparison

Photo by: Giorgio Piola

One of the most obvious areas of development, up and down the grid, is on the edge of the floor, with teams not only able to decide on whether to use an ‘edge wing’ but also the geometry of the floor’s edge and its discontinuity ahead of the rear tyre.

McLaren created a kerfuffle during pre-season testing when its interpretation of the edge wing was first seen. However, any wrongdoing was quickly snubbed out and several teams – including Ferrari – have since copied the design, having clearly seen promise when they conducted its own analysis on the design in CFD and the windtunnel.

While Mercedes hasn’t gone down McLaren’s route, its floor did feature an edge wing as part of the latest overhaul. The W13’s is more of a scythe shape and has allowed the team to alter the geometry of the floor that it flanks. Gurney-like flaps have been added on the floor’s periphery just ahead of the edge wing and the upswept section ahead of the rear tyre has also been optimised.

Red Bull Racing RB18 keel splitter comarison

Photo by: Giorgio Piola

Another area where teams have been monitoring the progress of rivals’ designs is the keel, with Aston Martin having set the wheels in motion on a solution that has found its way onto several other cars. Ferrari was the quickest respondent in this respect, as it had a version of the ‘bib wing’ ready for the launch of the F1-75 just a week after it was seen on the AMR22.

Red Bull swiftly followed, with the Alpine A522 and Mercedes W13 now also sporting versions of the winglet, along with optimisations to the shape of the keel to take advantage of the new flow conditions.

Red Bull has forged its own path in many respects, with the RB18 featuring one of the most highly refined floor designs on the grid. Unsurprisingly, some of those design features are now finding their way into rivals’ designs too, so let’s take a deeper dive into what Red Bull is doing…

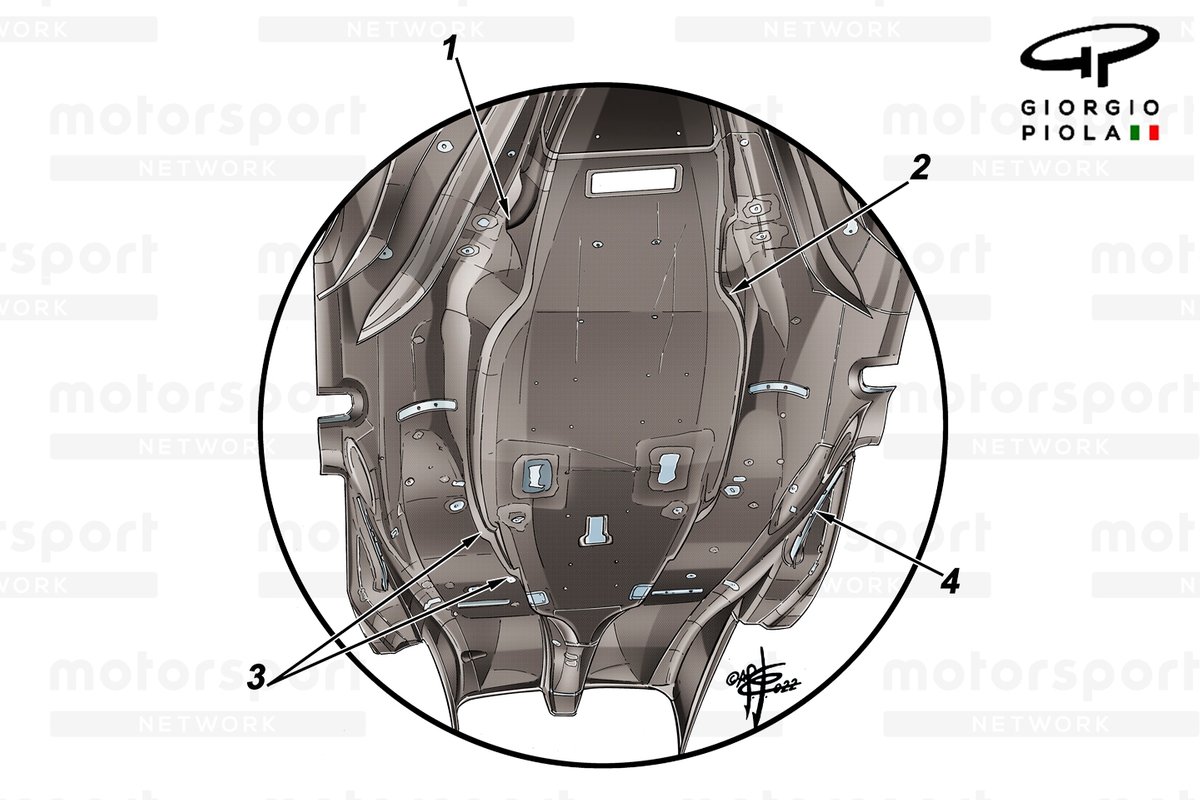

Red Bull Racing RB18 floor

Photo by: Giorgio Piola

The level of contouring seen on the underside of the RB18 is considerably different to what’s seen elsewhere. Whereas most teams appear to have a gentle curvature to the central boat-shaped section, Red Bull has an abrupt kink [2] roughly in-line with where the outwardly angled strakes terminate with the edge of the floor.

To soften this sudden transition there’s also a number of swages in the sidewall of the tunnel [1], which itself seems to have much more of a domed roof than many of the other solutions being used by its rivals. While this means it’s not utilising the maximum allowable space that the regulations permit, it likely reduces flow instability across a wider range of ride heights.

Red Bull has also employed a multi-step keel design as the floor tapers into the diffuser section at the rear of the car [3] and is a feature that Ferrari has incorporated into its latest redesign and something we’ve seen from McLaren too.

Ferrari F1-75 floor comparison

Photo by: Giorgio Piola

McLaren MCL36 floor

Photo by: Giorgio Piola

This region is not a one-size-fits-all solution, with each team sporting their own interpretation. For instance, the Red Bull and McLaren floors feature three steps, Ferrari’s has just the one.

Another interesting design feature of Red Bull’s to have hit the headlines recently is its ‘ice skate’. There were initially question marks over how it’s possible to have such a feature here, but it’s since become clear that it is Red Bull’s interpretation of the edge wing, housed underneath the floor, rather than on top.

The ice skate comprises a strake hung from the underside of the floor from the six allowable mounting brackets.

Red Bull Racing RB18 mini skirt detail

Photo by: Giorgio Piola

The brackets are made from metal, and so too is the strake, as the team has erred on the side of caution given it could come into contact with the track’s surface as the floor flexes towards the ground.

Although it’s not its primary function, the material choice might also result in the skate offering some rigidity to the floor too, although it might not be needed, as Red Bull has perhaps the most comprehensive internal stay strategy on the grid (see below).

The main function of the skate is aerodynamic, with a strake in this location, albeit not what was intended by the edge wing regulations, providing support for the various flow structures around it.

This will not only help to improve the performance of the underfloor tunnel but also reduce the ingress of tyre squirt into the diffuser section by altering the course of the airflow and vortices already in motion.

Red Bull RB18 floor detail

Photo by: Uncredited

Heading back topside, the team made an interesting change to the floor as part of the update package introduced in Spain. A large teardrop-shaped blister can now be found embedded in the floor beside the sidepod which appears to open up a route for the airflow to expand from within the sidepod to the channel that runs beside it (red arrows).

The air flowing through this channel then appears to exit out of a nozzle-shaped outlet further downstream (upper right inset), with the topography of the panel it’s housed within optimised to suit both the exiting flow and the external flow conditions.

The blister also appears to offer neat flow adjustment characteristics as the airflow moves around the sidepods undercut too (smaller, lower inset).

Red Bull RB18 Floor comparison

Photo by: Uncredited

More changes were made to the floor for Azerbaijan, as the team not only optimised the floor strake and boundary transition of the floor (blue arrows, old inset), but also the height and geometry of the floors leading edge.

Previously, the leading edge had dipped down to meet the chassis below the equator line resulting in the outer portion of the floor being higher than the inboard end (red arrow, old inset).

The leading edge has now been raised in this region and sits on the side of the chassis instead, resulting in different flow characteristics not only for the underfloor but also the airflow moving through the sidepod undercut.

Red Bull also finally found a need for the external floor stay that was introduced by the FIA ahead of the season to help teams mitigate the effects of porpoising.

The short wire stay required a small change to the floor to accommodate its anchorage, and it’s much shorter than many of its rivals as it intersects the floor sidewall beside it, rather than having to travel across the full width to the engine cover.

Red Bull Racing RB18 floor comparison

Photo by: Giorgio Piola